3-D Printed Robots Are Getting Solid and Liquid Insides Thanks to Scientists at MIT

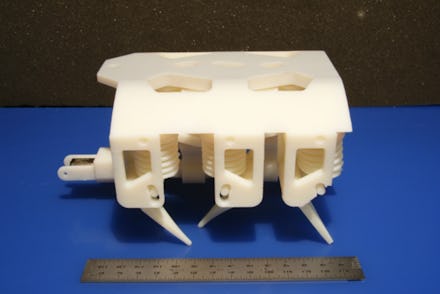

Researchers at the Massachusetts Institute of Technology's Computer Science and Artificial Intelligence Laboratory, or CSAIL, have developed a technique that allows for them to 3-D print robots with both solid and liquid materials. "Printable hydraulics" is a breakthrough in 3-D printing because it sets a precedent for functional machines that don't require extra assembly, which is great news for lazy people yearning for the day that robots can do their chores anyone who needs a robot to complete a complex task.

Read more: It's Finally Possible to 3-D Print Human Tissue — Here's How It Could Change Medicine

"All you have to do is stick in a battery and motor, and you have a robot that can practically walk right out of the printer," Daniela Rus, director of CSAIL and one of the co-authors of the study, said.

Adam Conner-Simons explains that liquids were a "big hurdle" when it came to 3-D printing. "Printing liquids is a messy process, which means that most approaches require an additional post-printing step such as melting it away or having a human manually scrape it clean," Conner-Simons wrote for MIT. "That step makes it hard for liquid-based methods to be employed for factory-scale manufacturing."

With CSAIL's technique, the 3-D printer's inkjet creates layers by incrementally depositing droplets of material that are thinner than the width of a human hair. Each layer can contain both photopolymer (a solid material) and non-curing material (which remain liquid); the parts of a robot that should be solid are then exposed to a high-intensity UV light.

Additionally, this technique allows for 3-D printers to print softer, more flexible materials, which can be used to create bellow actuators allowing for hydraulics movements and mobile parts.

In the same vein, softer materials can be used to create "fingers" capable of gripping.

Watch CSAIL's video demo below:

h/t Wired